In cases where after digitization there is a need to re-staple documents without using archive boxes, we use a device for stapling documents of their own design. This device provides high quality finished binders, even dilapidated documents, or those that are additionally bound in various ways during the long operation of archival affairs.

This device is a manual device for pre-stacking and subsequent stapling of documents and is used for binding and binding of archival documents for easy storage and transportation.

Unlike other similar devices for pre-stacking and subsequent stapling of documents, which have excess weight, size, high cost and technical complexity, this device provides high convenience and reliability in stapling documents and the quality of the finished file, suitable for mass production and use.

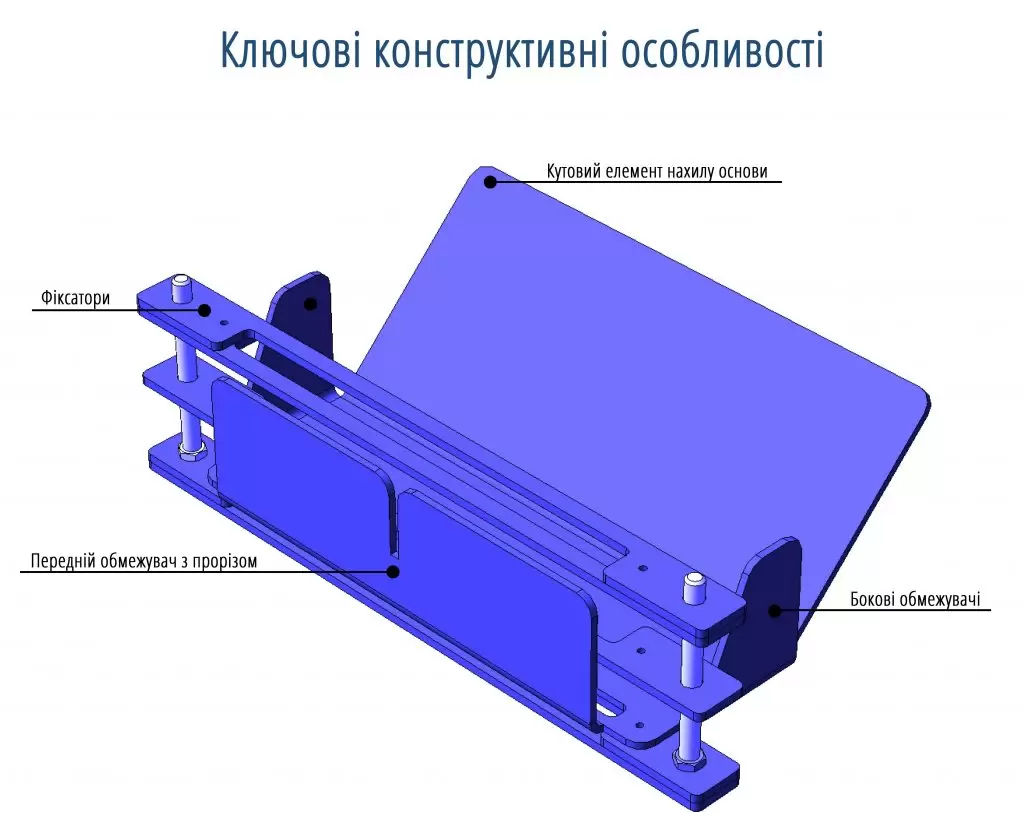

Among the disadvantages of similar devices critical for the work of archival documents is the lack of front limiter, and vice versa, its presence on the opposite side, which significantly limits the work with archival documents (which within one block may vary in size, density, age, condition, paper texture, etc. ), lack of possibility of partial step-by-step fixing of documents to eliminate the effect of paper slippage during laying, a large number of unique components, which increases the cost of manufacturing and maintenance of the device, low reliability in daily use on an industrial scale, unjustifiably limited use in modern industries. use with known automatic stitching machines. Also, similar devices provide binding of documents only with the fixed size of the field for binding.

That is why the task of developing a device for stapling documents, which will be free of all these shortcomings, was set at the forefront. It was solved by introducing new design features of this device.

During the process of compiling archival documents that differ within one block in size, density, age, condition, paper texture, etc., between the side and front delimiters and subsequent pressing and fixing of archival documents, the angular tilt element prevents some documents from slipping under pressure and promotes alignment relative to the front limiter, front limiter and side limiters ensure alignment of different types of documents relative to two perpendicular edges of the block without the participation of the operator. Due to the use of several separate clamps, it is possible to partially fix the documents in stages to eliminate the effect of slipping paper during stacking. Due to the use of a pair of the same clamps as a clamp, the versatility and ergonomics of the device are ensured.

During the process of compiling archival documents that differ within one block in size, density, age, condition, paper texture, etc., between the side and front delimiters and subsequent pressing and fixing of archival documents, the angular tilt element prevents some documents from slipping under pressure and promotes alignment relative to the front limiter, front limiter and side limiters ensure alignment of different types of documents relative to two perpendicular edges of the block without the participation of the operator. Due to the use of several separate clamps, it is possible to partially fix the documents in stages to eliminate the effect of slipping paper during stacking. Due to the use of a pair of the same clamps as a clamp, the versatility and ergonomics of the device are ensured.

The technical result provided reliability, ease of use and, as a consequence, reduction of labor costs, time and money for the manufacture of binders and its long service life.

*Text translated automatically